|

Blenders IBC Blending System Pharma Lifter Washing Station |

|

VANGUARD'S VZD

Pharma IBC Blending System is a first class blending equipment

that yield superb mixing uniformity of powder and other great

advantages over other type of blenders. It consists of an

Intermediate Bulk Container, rotary frame, driving system, lifting

system, braking and SIEMENS PLC Touch Screen Control System. The

operation is very simple: place the bin into the rotary frame, and

press the confirmation button on the touch screen. The bin is then

lifted to the required height and clamped. The driving system

starts to work and mix accordingly to the time and speed assigned

after the pressure sensors receive signal of tightly clamped.

Reaching to the parameters assigned, the braking system starts to

work and the rotary frame stops vertically. The mixing production

is finished. The lifting system then works accordingly to lay down

the bin. Pull the bin out from the rotary frame (can also separate

materials from the bin directly in the frame) and the printer

prints the entire production data. The working cycle has finished.

The structure trait of VZD IBC Blender is the rotary frame (bin)

and the mixing axis make of an angle, the movement of the

materials inside the bin contains the wall of bin. This will yield

a uniform and perfect mix.

First Class

Blending System + Immediate & Long Run Cost Savings: A bin blending system offers considerable savings. Consider the following points: Multiple shell blenders can be replaced, the entire blending operation can be done in one small room. Cross contamination is a non-issue as product will not be exposed to the blending room environment. Reduced Labor Costs. Fixed shell blenders take a long time to fill and empty. Compared to bin blending, there can be as much as twice the material handling. Generally, fixed shell blenders are loaded from the floor above by gravity or by a vacuum. This means that all the products have to be handled from the dispensary (weighing area) and then discharged again into the blender (versus loading directly in the bin). As opposed to bin blending, the loading process is usually dusty, not ergonomic, and labor intensive. In a bin blending operation, the materials are loaded directly into the bin, which can take place in the dispensary and easily done in a high-containment method. Increase Product Quality. Fixed shell blenders require the products to be transferred after blending into a drum or bin. Every time the product is transferred, some segregation can take place. In a bin blending operation, the product is transferred to the next operation directly from the bin (blending container). Furthermore, in many operations one or two steps that used to require that the product be exposed to the room or additional fall tubes, vacuum systems, etc., can be eliminated, thereby reducing the chance of foreign substances entering the product. Increase Finish Product Output: Your total amount of blends per day is only limited to the amount of bins. Example: if you have 20 bins you can have 20 finished blends a day. The reason is that you dont have to clean the base unit. Thus giving you up-time savings.

The IBC can also we used to feed tablet presses, capsule machines,

powder fillers and etc. This employs the use of a pharma bid lifter; Thus reducing dust and cross contamination. . |

|||

|

|

||

Technical Specifications:

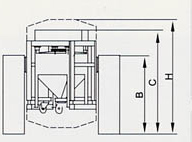

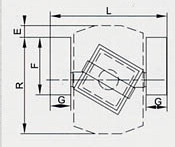

| Parameters \ Type | VZD -400 | VZD - 600 | VZD - 800 | VZD - 1000 | VZD - 1200 | VZD - 1500 | VZD - 1800 | VZD - 2000 |

| B | 1820 |

1900 | 2050 | 1970 | 2180 | 2180 | 2220 | 2350 |

| C | 2410 | 2540 | 2710 | 2760 | 2940 | 3050 | 3780 | 3420 |

| H | 2810 | 2980 | 3210 | 3350 | 3540 | 3560 | 3620 | 3860 |

| L | 2470 | 2940 | 2940 | 3310 | 3310 | 3500 | 3500 | 3500 |

| E | 460 | 210 | 350 | 470 | 510 | 480 | 500 | 620 |

| R | 1950 | 2330 | 2470 | 2590 | 2630 | 2780 | 2800 | 2900 |

| F | 1100 | 1440 | 1440 | 1440 | 1440 | 1550 | 1550 | 1550 |

| G | 420 | 520 | 520 | 520 | 520 | 600 | 600 | 600 |

| Power (kW) | 4 | 5.5 | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 |

| Weight (kg) | 1,800 | 2,500 | 2,800 | 3,000 | 3,200 | 3,700 | 4,000 | 4,200 |