|

Capsule Filling Capsule Polisher

|

VAF-2500C Automatic Capsule Filler |

||

|

||

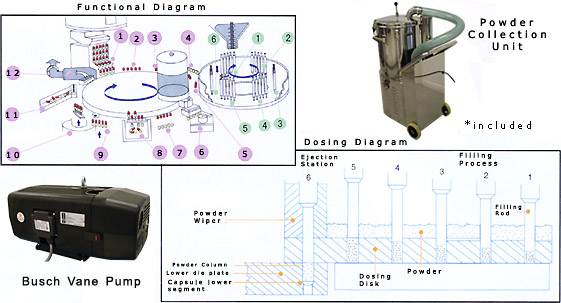

| Dosing Filling Process: 1. The powder column is compressed to be 1/5 thickness of dosing disk. 2. The powder column is compressed to be 2/5 thickness of dosing disk. 3. The powder column is compressed to be 3/5 thickness of dosing disk. 4. The powder column is compressed to be 4/5 thickness of dosing disk. 5. The powder column is compressed to be same as the thickness of dosing disk. 6. Fill the compressed powder column of proper dosage into capsules. |

Functional Process: 1. The capsules are fed to the segments in sequence, the cap and body are separated by means of a vacuum suction. 2. Transporting 3. Cap and body are separated and prepared for filling. 4. Powder column filling 5. Optional pellet and tablet filling 6. Eject the faulty capsules 7. Transporting 8. Joining of capsule body and cap 9. Eject finished product 10. Clean the segments. |

|

|